Reverse Osmosis

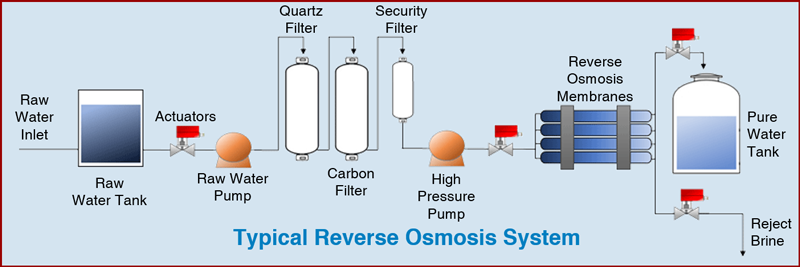

Reverse osmosis (RO) systems are widely used for purifying water, from desalination of seawater to producing ultra-pure water for various industrial applications. In these systems, the efficiency and reliability of the water supply and pressure is very important. MTH Pumps regenerative turbine pumps are an excellent choice for boosting efficiency and ensuring smooth operation in reverse osmosis systems. In this article, we will explore the key benefits of using regenerative turbine pumps and provide a step-by-step guide on how to incorporate them into your RO setup.

Understanding Regenerative Turbine Pumps

Regenerative turbine pumps, sometimes referred to as peripheral pumps or vortex pumps, are a type of centrifugal pump made for high pressure with low to moderate flows. Unlike typical centrifugal pumps, which rely on curved vanes to draw liquid from the center of an impeller to generate flow, regenerative turbine pumps use an impeller with vanes on the outer diameter that closely interact with a stationary water channel. This unique design produces high-pressure with low to moderate flows during operation. Regenerative turbine pumps are known for their ability to provide stable, pulsation-free flows and high pressure, making them an excellent choice for various applications, including reverse osmosis systems.

Advantages of Using Regenerative Turbine Pumps in RO Systems

- High Efficiency: Regenerative turbine pumps are highly efficient, especially in low-flow, high-pressure applications like reverse osmosis. Their ability to generate high pressure without overtaxing the system can significantly reduce energy consumption, resulting in cost savings over time.

- Stable Flow: The design of regenerative turbine pumps ensures a consistent and stable flow rate, which is critical for reverse osmosis systems. Fluctuations in flow can negatively impact the performance of the RO membranes, potentially reducing their lifespan and effectiveness. Regenerative turbine pumps help maintain steady and pulsation-free flow.

- Compact Size: Regenerative turbine pumps are relatively compact, making them ideal for applications where space is limited. Their small footprint is especially valuable in industrial settings where equipment density is a concern.

- Low Noise and Vibration: These pumps are known for their quiet operation and low vibration levels, contributing to a more comfortable working environment. This is particularly important in commercial and residential applications.

How Regenerative Turbine Pumps are used in a Reverse Osmosis Systems

Now, let's discuss how to incorporate regenerative turbine pumps into your reverse osmosis system.

- System Assessment: Begin by assessing your existing reverse osmosis system. Identify the required flow rate and pressure, considering factors like the number of RO membranes, feedwater quality, and the desired product water quality.

- Pump Selection: Select a regenerative turbine pump that matches your system's requirements. Ensure that the pump's performance curve aligns with your flow and pressure needs. Consulting with a pump expert or manufacturer can be helpful in making the right choice.

- Installation: Install the regenerative turbine pump into your RO system's feedwater line. Position it after any pre-filtration components to avoid damage to the pump impeller. Proper installation is critical to ensure optimal performance.

- Electrical Connections: Connect the pump to the power source following the manufacturer's instructions. Ensure that the electrical components are installed correctly to prevent electrical issues and safety hazards.

- Monitoring and Maintenance: Implement a routine monitoring and maintenance schedule for the regenerative turbine pump. Regularly inspect the impeller, water channel, and seals for any signs of wear or damage. Replace parts as needed to prolong the pump's lifespan.

- Performance Optimization: If using a variable frequency drive and/or relief valves, adjust the pump's operating speed and control settings to meet the specific demands of your reverse osmosis system. This may involve fine-tuning the pressure and flow rates to ensure optimal RO membrane performance.

Regenerative turbine pumps offer a range of advantages when used in reverse osmosis systems, including high efficiency, stable flow, compact size, and low noise. By following the steps outlined in this guide, you can successfully integrate a regenerative turbine pump into your RO system, ultimately improving its performance, reliability, and cost-effectiveness. Whether in industrial or residential settings, these pumps are a valuable addition to any reverse osmosis setup, helping ensure the efficient production of high-quality purified water.