Custom Engineered Products

MTH's goal to develop and produce pumping products that address the needs of both OEM's and end users alike has driven the company to become highly vertically integrated. Towards this end, the acquisition of resources to rapidly design and develop pumping solutions specific to the customer's application needs has been paramount.

In-house Capabilities: «Click here to view our specialized In-house Capabilities

Special Customer Projects: «Click here to learn about some of our Special Customer Projects

MTH begins the development process by researching the needs of the customer and the application requirements. Research projects with the customer's equipment brought in-house and tested in a simulated operating environment, is often used to aid in the development of design input specifications. At the heart of this process is the desire to find a solution to pumping problems that traditionally plague the industry or application in question. In each major industry MTH endeavors to become the most capable source of pumping knowledge available, thereby providing our customers with an additional engineering resource that can be leveraged to increase their product's advantage in the marketplace. Not lost in this effort, is the desire to meet the ongoing needs of the OEM to reduce cost, extend product life, reduce maintenance, and add product capabilities.

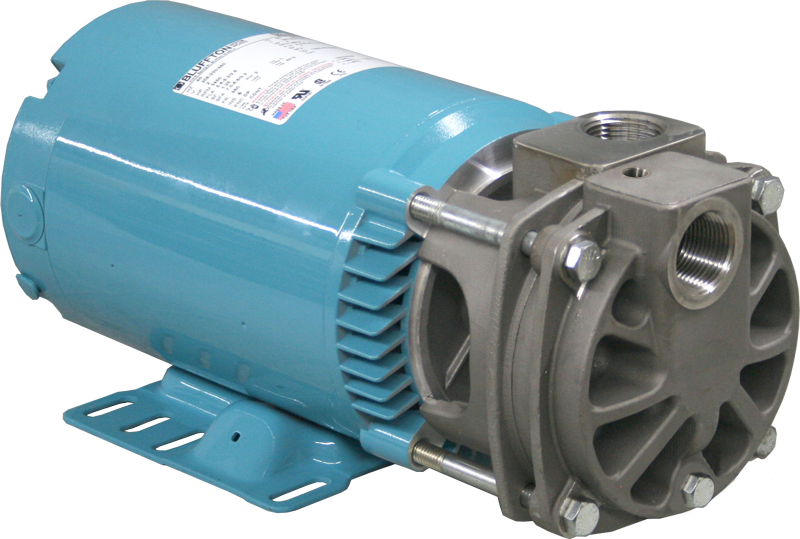

With basic design specifications in mind, MTH enters a rapid design / prototyping / testing cycle where newly designed or modified standard product can be evaluated for performance, reliability, and cost of manufacturing. The result is a custom engineered product offering that specifically addresses customer and application needs while very often reducing the cost of the overall product. MTH has been very successful at producing and selling custom engineered products at a cost less than that of commonly available standard pumps.

MTH's efforts to surpass customer satisfaction extend well beyond the pump itself. Special mounting brackets, piping trees, construction materials, custom assembly / packaging / testing services, inventory stocking arrangements, and JIT shipping schedules are all a part of the solution that our existing customers have found in a valuable product partner that is MTH Pumps. Please select from the links above for more information on some of our custom engineered products or go to our Pumping Product Types and Applications sections to help determine where to start.

Contact us now with your special needs or questions.

Download our Custom Engineered Pump Design Applications form to have one of our highly skilled application engineers help you selct the pump you need!

HP31 • HP41 • HP412 Hermetic Regenerative Turbine Freon & CO2 Pumps

Pump Characteristics |

|

X41 Series Pumps

Pump Characteristics |

|

MDT (MTH DAF Turbine) Regenerative Turbine Pumps

Pump Characteristics |

|

ST31 • SE41 • SE51 • SM50 • SL50 Series Sealless Pumps

Pump Characteristics |

|

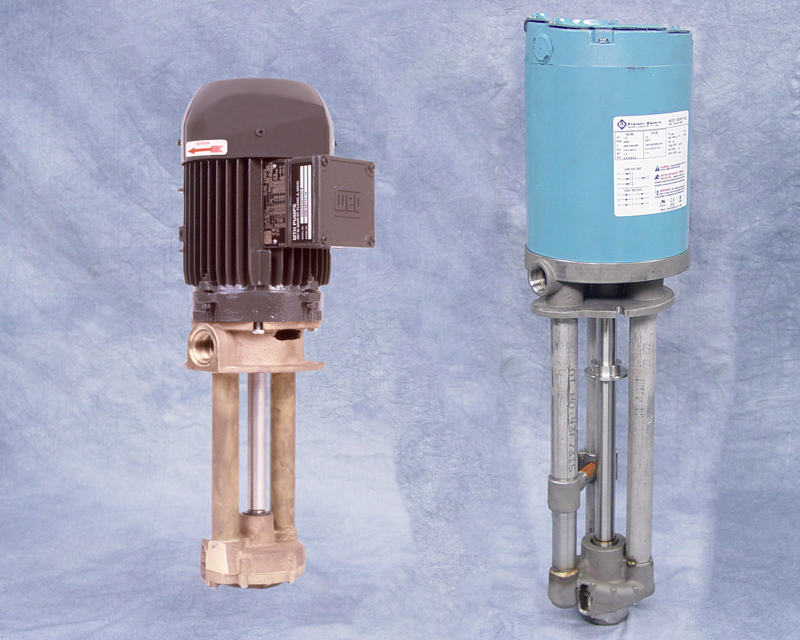

S31 • S41 • S51 Series Immersible Pumps*

Pump Characteristics |

*S31 • S41 • S51 Series Immersible Pumps are past projects that tout MTH’s engineering & manufacturing abilities and are not currently available. However, these models (or a version of these models) could be produced again under the right circumstances. |

ST21 Series DC Brushless Pumps

Pump Characteristics |

*ST21 Series DC Brushless Pumps are a past project that tout MTH’s engineering & manufacturing abilities and are not currently available. However, these models (or a version of these models) could be produced again under the right circumstances. |

SC31 Series DC Brushless Pumps

Pump Characteristics |

*SC31 Series DC Brushless Pumps are a past project that tout MTH’s engineering & manufacturing abilities and are not currently available. However, these models (or a version of these models) could be produced again under the right circumstances. |