HP Series Hermetic Regenerative Turbine Freon, A2L's, CO2, & other Refrigerant Pumps

Save Energy & Reduce Carbon Footprint with an HP Series Pump at the Root of Your Cooling & Refrigeration System!

- Capacities to 45 GPM

- Heads to 450 Feet

- Temperatures to 150°F (66°C)*

- Sealless

- For Non-conductive Fluids

- For Non-corrosive Fluids

- Inverter Duty Motor

* Consult factory for higher temperatures.

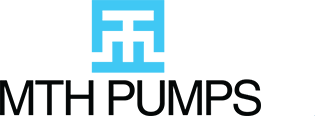

HP31 Series Pump Information

|

Pump Characteristics

|

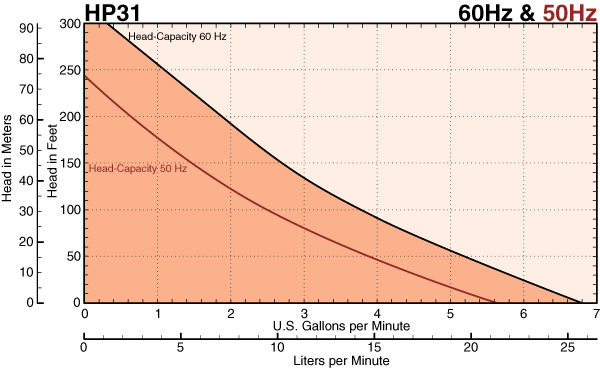

HP41 Series Regenerative Turbine Pumps

|

Pump Characteristics

|

MTH Pumps HP Series

The HP31, HP41, and HP412 Series line of hermetically sealed regenerative turbine pumps (also known as hermetic or zero emission pumps) is designed to handle applications with difficult to seal, non-conductive, non-corrosive fluids such as freons, A2L's, CO2, and others, where absolutely leak free performance is required, and mechanical seals simply cannot provide the needed reliability, protection, and performance. All of this is accomplished at a price point previously unseen in the industry, and is often comparable with other mechanically sealed solutions, but without the leaks and inevitable seal maintenance. Exotic non-conductive fluids present no difficulty for these units at fluid temperatures from -58°F (-50°C) up to 150°F (66°C). The hermetic design is far preferable to magnetic drive couplings as it does not add excessive length to the unit in tight OEM enclosures, or suffer from the magnetic de-coupling problems often associated with mag-drive solutions. Two bearings, high strength cast steel components, and CNC welded seal-less design assure extended maintenance free life.

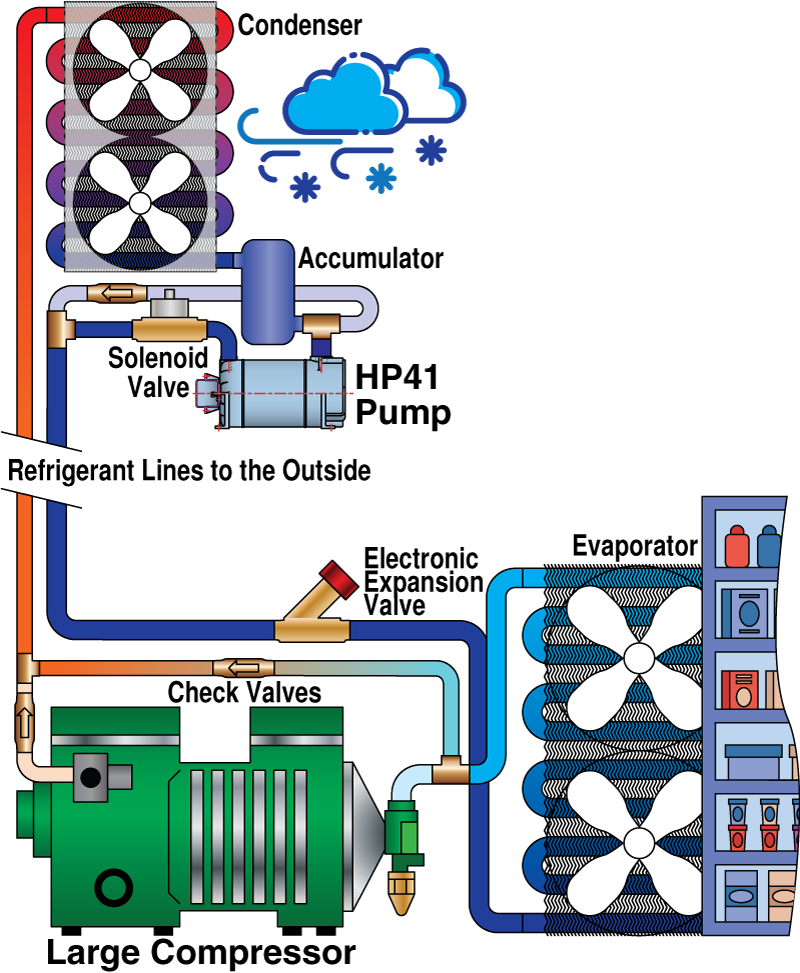

HP Series in Practice

When the outside temperatures become low enough to maintain the desired cooling temperature, there is no need to compress the refrigerant to a higher pressure/ temperature.

During colder outdoor temperatures, the system can be switched from running the high electricity consuming compressor to running the much lower horsepower pump and power consumption can be saved.

Note: This is a simplified representation for conceptual purposes only. A pumped liquid refrigerant system must be designed by a competent, qualified refrigeration engineer.

Design Features

Steep Operating Characteristics

Near-constant fluid delivery is maintained over wide variations in discharge pressure. High shut-off pressures can often overcome temporary line resistances to maintain flow. Superior to Centrifugal pumps when dual speed 50-60 Hertz operation is desired.

Several Sizes Currently Available

Our current models include the HP31F, HP41E, HP41J, HP41P, and HP412P. Horsepowers range from 1 1/2 up to 7 1/2. Contact factory if greater pressures and flows are needed.

Self-Adjusting Impeller

A hydrodynamic film on each side of the impeller centers it in the casing and minimizes friction, which lengthens pump life. The impeller also exerts no axial thrust load on the bearings.

Leak Free Sealless Design

The hermetically sealed pump/motor combination uses the process fluid itself for cooling. Ends down time and maintenance problems associated with mechanical seals. Environmentally safe leak-free design. Each and every pump is tested for barrier and containment integrity before shipment.

Non-Cavitating

Sealless Turbine pumps may be operated under adverse inlet conditions without audible or measurable cavitation if fluid begins to vaporize.

Best Efficiency

Designs optimize best efficiency for each size.

Low NPSH Requirements

Like its T31 and T41 Series mechanically sealed counterparts, the HP Series hydraulic passageways are designed to minimize thrust on the self-adjusting impeller to avoid upsetting its hydraulic balance, and to handle low NPSH conditions which can occur in some applications. New to the HP Series is the location of the inlet on the centerline of the impeller to further eliminate the potential of axial imbalance that sometimes occurs during periods of marginal NPSH availability. With these design features, MTH has eliminated almost all of the bearing thrust loads in these units, and the motor thrust bearings exist only to provide axial rotor positioning. Proper vapor or air purging at startup will help assure that the bearings are properly lubricated and minimize startup wear and priming problems. Rotolock fittings are used for both of these openings to assure a reliable leak-free fit, and to minimize the potential of galling that can be troublesome if over-tightening should occur.

Compact Integrated design

The pump/motor units use two carbon bearings, with the motor rotor positioned between two thrust bearings and the impeller overhung to provide long running life. As with all plain bearing pumps, keeping pumping systems free of solids to prevent bearing failure is important.

HP Series Bulletin

Custom Engineered Products