140 • 240 • 180 • 280 Series Regenerative Turbine Pumps

Design Features |

|

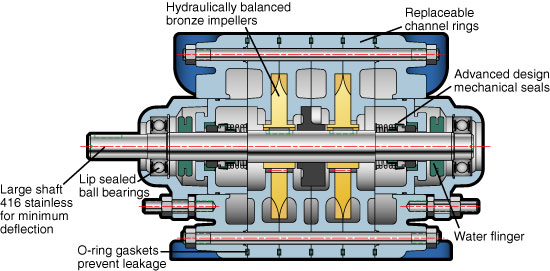

Steep Head/Capacity CurvePumping capacity varies only slightly as pressure changes. Steep pressure characteristic overcomes temporary line resistances. Self Adjusting Impeller140/180 Series impellers utilize balancing holes to promote hydraulic self-centering and to elimanate the need for external adjustment. The impeller exerts no thrust load on the bearings, thereby extending service life. 400# Case Working PressureRigid structure is designed for maximum casing stregth. 100% TestedEvery pump is fully tested to verify performance prior to shipment. Volitile Fluid HandlingThe turbine impeller handles vapors up to 20% by volume, minimizing the possibility of vapor lock. Mechanical SealsBronze fitted pumps have EPR rubber, high temperature carbon and ceramic seats for best hot water service. Optional seats and materials are availible. |

“O” Ring Gaskets“O” ring seals are used throughout the 140/180 Series pumps to assure positive sealing. ShaftPump shaft is high strength 416 stainless steel material. BearingsHeavy duty sealed ball bearings on inboard and outboard ends of the shaft are permanently lubricated for maintenance free service. Water FlingersWater flingers provide added protection to ball bearings in the event of seal leakage. Best EficiencyNew pump designs optimize efficiency for each size available. Non-Cavitating140/180 Series pumps may be operated under adverse inlet conditions without audible or measurable cavitation. Low NPSHNew inlet design provides supior fluid handling ability with low head inlet condition.

|

|

|

|

Click here to return to the 140 • 240 • 180 • 280 Product Information Page.