Standard Products Guide

Regenerative Turbine Pumps Centrifugal Pumps

Single Stage Close-coupled Turbine Products

MTH Pumps is a commercial and industrial pump manufacturer serving a wide variety of markets and industries including boiler feed, condensate return, chillers / temperature controllers, water services, refrigeration, petroleum, as well as many chemical process applications. Our Standard Product lines include mechanically sealed regenerative turbines for low flow, high pressure, applications (up to 1000PSI / 150GPM) as well as two lines of small centrifugals (155PSI / 230GPM). All pumps are tested before shipment. We also offer custom engineered products such as seal-less canned versions of our turbine product lines. In fact, to our knowledge, MTH Pumps offers the broadest line of regenerative turbine and seal-less canned pump products available in the world. We also have extensive experience in custom designing pumps for specific OEM needs where high reliability and cost reduction are a primary concern. If you don’t find what you are looking for in the Standard Products you see within this brochure, please consult our website at www.MTHPumps.com or contact us at Sales@MTHPumps.com.

|

P31 Series

MTH P31 Series regenerative turbine pumps handle capacities up to 4 1/2 gallons per minute and 250 feet of head at temperatures up to 250°F. These units feature an adjustable casing to provide variable performance output or readjustment of worn internal clearances to extend service life. Its compact size and top suction and discharge allow for installation in tight enclosures. These units feature stainless steel casings. Standard construction includes a bronze impeller, a carbon/ceramic seal, and Viton elastomers. All P31 pumps can mount onto ultra compact 36 Frame UL and CE approved motors, as well as our dual face D3 motors. Optional motors with higher horsepower, solid state starting, TEFC enclosures, and 3 phase capabilities are also available. OPTIONAL FEATURESAll Stainless Steel and RoHS compliant versions are available. A built-in relief valve is also available. The relief valve temporarily protects against dangerous over-pressure. All relief valves are preset at the factory to your specifications (60 to 100 psi range available). |

|

T31 • E41 • E51 Series

The T31, E41, and E51 Series close-coupled regenerative turbine pumps utilize our custom manufactured dual face 3450RPM D3 motors that incorporate a 304 stainless steel shaft and heavy-duty bearing. The stainless steel shaft eliminates the necessity of a shaft sleeve, thereby reducing the parts count and simplifying OEM maintenance and servicing procedures. All D3 motors also feature a two-pole 50/60Hz rating, as well as UL and CE approvals useful for OEM’s with worldwide customers. The three-phase versions of the D3 motors feature a compact TEFC enclosure and a range from 1/3 to 3HP. The single phase D3 motors have an ODP enclosure and a range from 1/3 to 2HP. The E41 and E51 are also available in a close-coupled vertical flange mount configuration. Standard construction includes a bronze impeller, a carbon/ceramic seal, and buna elastomers.

The T31, E41, and E51 Series close-coupled regenerative turbine pumps utilize our custom manufactured dual face 3450RPM D3 motors that incorporate a 304 stainless steel shaft and heavy-duty bearing. The stainless steel shaft eliminates the necessity of a shaft sleeve, thereby reducing the parts count and simplifying OEM maintenance and servicing procedures. All D3 motors also feature a two-pole 50/60Hz rating, as well as UL and CE approvals useful for OEM’s with worldwide customers. The three-phase versions of the D3 motors feature a compact TEFC enclosure and a range from 1/3 to 3HP. The single phase D3 motors have an ODP enclosure and a range from 1/3 to 2HP. The E41 and E51 are also available in a close-coupled vertical flange mount configuration. Standard construction includes a bronze impeller, a carbon/ceramic seal, and buna elastomers.

OPTIONAL FEATURES

Construction materials of all iron (except T31), all bronze, and 316 stainless steel are available. Special seal materials, elastomers, and internal seal flush are available for temperature and fluid compatibility.

Single Stage Turbine Products

|

|

|

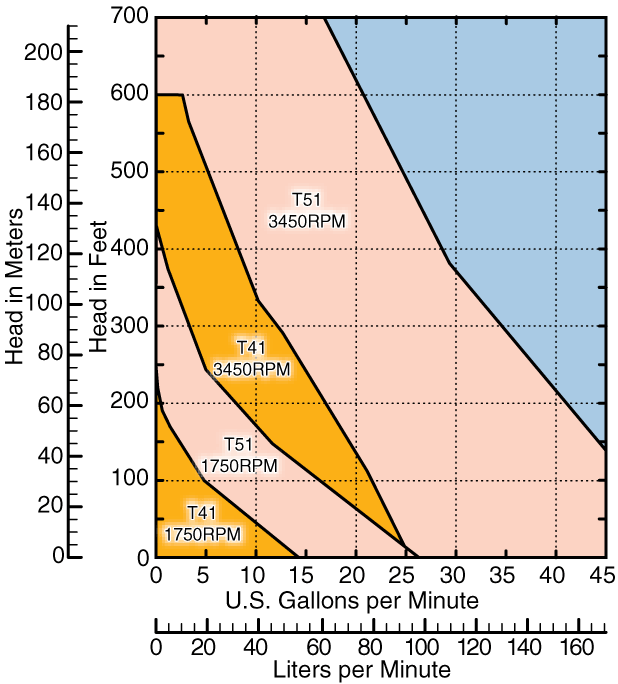

MTH T41 and T51 Series regenerative turbine pumps, like their E41 and E51 OEM versions, offer excellent performance in low flow, high head, clean fluid applications, but offer additional mounting and motor options for extended range and more specialized services. Like all of our turbine products, these units combine the latest concepts in turbine hydraulic design optimization, with computer controlled manufacturing, to produce high efficiency and performance with low NPSH requirements. These easily serviceable pumps provide long life in clean fluid applications featuring a floating, self-adjusting impeller design with no metal to metal contact. This design is especially suited to high purity and low fluid lubricity applications where the carbon vanes and metal gears of many positive displacement pumps are troublesome. Regenerative turbine impellers also effectively handle high percentages of entrained vapor to help reduce the possibility of vapor lock. All pumps are 100% tested to guarantee performance prior to shipment.

CONSTRUCTION

Standard construction is cast iron bronze fitted. Internal wetted cast iron parts are electroless nickel-plated and the double-sided bronze impeller is hydraulically balanced to minimize wear. T Series pumps offer a replaceable shaft sleeve for maximum fluid compatibility. Standard seals are rated for 230°F Water.

OPTIONAL FEATURES

Construction materials of all iron, all bronze, and 316 stainless steel are available. Pumps can also be pedestal mounted for flexible coupling drive by almost any type of motor. Special seal materials, elastomers, internal seal flushes, and seal cooling jackets are available for temperature and fluid compatibility. Sealless canned ST41 and ST51 Series are also available.

T41 • T51 Mounting Options

High Pressure Multi-stage Turbine Pumps

M50 • L50 Series

MTH M50 and L50 Series Regenerative Turbine Pumps are multi-stage versions of the popular T51 Series and are ideally suited for low flow applications (2 to 38 GPM) requiring higher discharge pressures than those available from a single stage unit. Head pressures to 2300 feet are available in a five stage M55. Both the M50 and L50 Series are available in close coupled, vertical base mount and horizontal pedestal base mounted configurations.

MTH M50 and L50 Series Regenerative Turbine Pumps are multi-stage versions of the popular T51 Series and are ideally suited for low flow applications (2 to 38 GPM) requiring higher discharge pressures than those available from a single stage unit. Head pressures to 2300 feet are available in a five stage M55. Both the M50 and L50 Series are available in close coupled, vertical base mount and horizontal pedestal base mounted configurations.

For applications with low vapor pressure fluids, or where NPSH availability is low, the L50 Series adds a low NPSHR centrifugal inducer stage to help feed the high pressure regenerative turbine stages. Standard 56C face motors are used up to 3 HP. Vertical base mount pump motors 5 HP and larger are TEFC enclosure. Pedestal base mount pumps utilize standard rigid base motors.

CONSTRUCTION

Standard construction is cast iron bronze fitted. Iron parts are hard electroless nickel plated. Impellers are bronze, hydraulically balanced, and self-centering to minimize side wear. Pump shafts are 416 stainless steel, while interstage bushings are carbon/graphite in a stainless steel cartridge. Pump bearing pedestal and motor are furnished with permanently lubricated sealed ball bearings for maintenance free service. “O” ring gaskets are utilized to assure sealing and for ease of maintenance. Standard mechanical seals are rated for 230°F water operation and furnished with a flush line on multi-stage pumps. All pumps are 100% tested to verify performance prior to shipment.

OPTIONAL FEATURES

All iron, all bronze, and cast 316 stainless steel construction is available from stock. Buna, EPR, Viton, Neoprene and Teflon “O” ring and seal elastomer materials, as well as silicon carbide, tungsten carbide, ni-resist, and graphite loaded silicon carbide seal seats are also available. For seal-less canned versions of these units, see the SM50 and SL50 Series.

|

L50 Series Inducer |

Turboflex Multi-stage Turbine Pumps

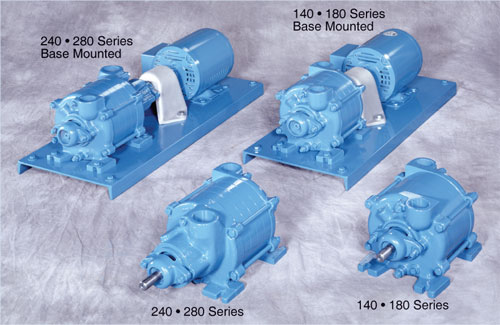

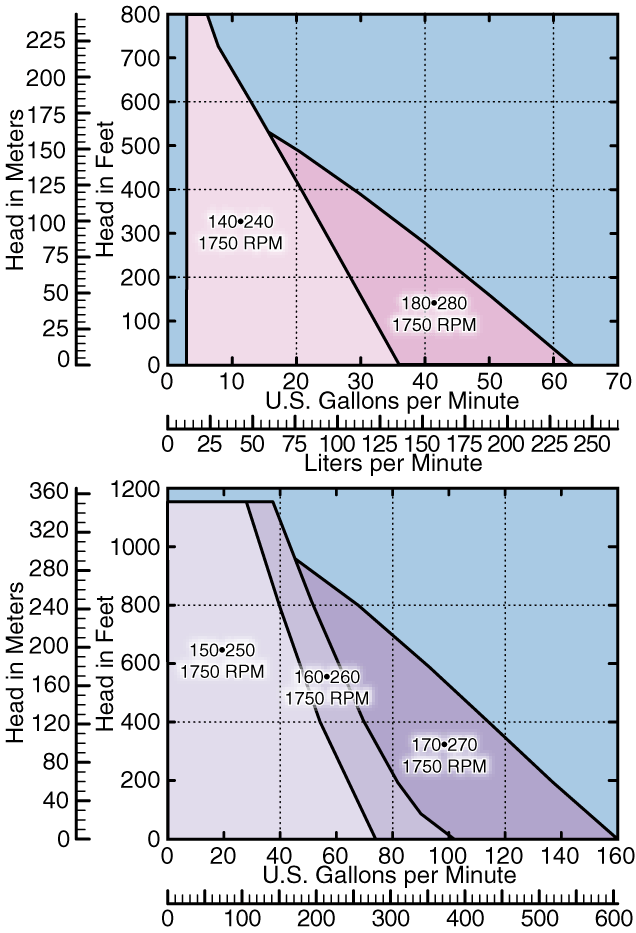

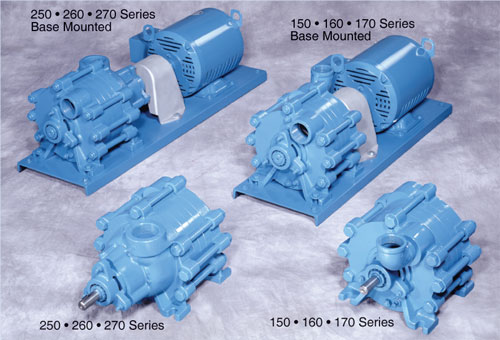

140 • 240 • 180 • 280 Series

MTH Turboflex radially split foot mounted 100 and 200 Series regenerative

turbine pumps offer the high pressure characteristics of a multi-stage

pump (heads up to 1150 feet) at flow ranges beyond those available in

any of our other regenerative turbine products (up to 150 GPM). These

heavy duty industrialized units also utilize the latest concepts in regenerative

turbine hydraulic design, and benefit from tightly computer controlled

manufacturing techniques. Turboflex pumps feature 1750 RPM motors to

deliver long life and high efficiency performance with low NPSH requirements.

For applications with NPSH availability as low as one foot, the 200 Series

adds a centrifugal style inducer in front of the turbine stages. Like

our other turbine products, the multi-vane turbine impellers handle entrained

vapors to help reduce the possibility of vapor lock in boiler feed water,

ammonia, and other refrigerant services.

MTH Turboflex radially split foot mounted 100 and 200 Series regenerative

turbine pumps offer the high pressure characteristics of a multi-stage

pump (heads up to 1150 feet) at flow ranges beyond those available in

any of our other regenerative turbine products (up to 150 GPM). These

heavy duty industrialized units also utilize the latest concepts in regenerative

turbine hydraulic design, and benefit from tightly computer controlled

manufacturing techniques. Turboflex pumps feature 1750 RPM motors to

deliver long life and high efficiency performance with low NPSH requirements.

For applications with NPSH availability as low as one foot, the 200 Series

adds a centrifugal style inducer in front of the turbine stages. Like

our other turbine products, the multi-vane turbine impellers handle entrained

vapors to help reduce the possibility of vapor lock in boiler feed water,

ammonia, and other refrigerant services.

CONSTRUCTION

Standard construction is cast iron bronze fitted. Suction and discharge covers, seal cups, bearing arms and casing channel rings are cast iron material. Pump shaft is high strength 416 stainless steel. Impeller is cast bronze, hydraulically balanced and self-adjusting for longer life. Sealed ball bearings are permanently lubricated for maintenance free operation. “O” ring gasketing is used to assure sealing and for ease of maintenance. Standard mechanical seals are rated for 230° F water operation. All units are flexible-coupled for easy service and motor flexibility. Pumps are 100% tested to guarantee performance prior to shipment.

OPTIONAL FEATURES

Turboflex pumps are also available in all iron, all bronze, and 316 stainless steel construction. Silicon & tungsten carbide seal seats, EPR/Neoprene/Teflon/Viton “O” ring gasket materials, external seal flush, and balanced or double mechanical seals are also available. For low NPSH/low vapor pressure fluid service, the 200 Series adds an inducer stage. Reduced NPSHR is obtained by using a centrifugal inlet impeller along with a multi-vane diffuser to provide the second stage regenerative turbine with adequate suction head. NPSHR is reduced to as low as one foot on 240 • 280 Series pumps and as low as two feet on 250 • 260 • 270 Series pumps. Sealless canned models will be available in the future.

|

150 • 250 • 160 • 260 • 170 • 270 Series

|

|

Compact Centrifugal Pumps

C41 • C51 • C61 Series

|

|

|

Engineered Products and Accessories

The mission of MTH Pumps is to design, develop, and produce pumping products to fit applications in which they are technically correct solutions that also address the peripheral needs of the customer. To this end, the company has endeavored to become highly vertically integrated to maximize the flexibility and agility of the company to meet product and customer needs. To facilitate the engineering centered nature of the company, MTH has acquired a number of resources needed to bring it to the leading edge of engineered product design and development. MTH utilizes highly experienced design engineers, solid modeling CAD software, rapid prototyping equipment, its own pattern and mold making shop, its own foundry and fabrication shop, state of the art auto-loading CNC machining equipment, and a wealth of inspection and testing equipment to rapidly design and develop the right solution for the job. In many cases, the design of custom pumps and accessories has netted a significant cost savings to the customer over the use of standard off the shelf products. Whether the customer is looking for a slight modification to one of our standard products, a totally new pump design, or a completely different kind of product, MTH has the broad range of resources required to complete the task.

MTH Pumps In-house Capabilities Include:

- Creative Engineering services

- Solid modeling design

- Rapid Prototyping tools

- Pattern and mold making shop

- Bronze and Aluminum casting foundry (casting services inquiries invited)

- Highly automated state-of-the-art CNC machine shop

- Complete Metal Fabrication Facility (fabrication services inquiries invited)

- Custom designed assembly/testing equipment and facilities

- Customized packaging and labeling capabilities

- Large finished inventory capacity for high availability and rapid shipment

- Dedicated Service and Repair Facility

While MTH Pumps’ primary talents lie in engineering design, our efforts to meet and exceed customer specifications and satisfaction extend beyond the engineering and manufacturing arena. Special sourcing arrangements, construction materials, custom assembly, packaging, labeling, and testing services, quality surveillance, inventory stocking arrangements, and JIT shipping schedules are all a part of the solution that our existing customers have found in a valuable product partner that is MTH Pumps.

In the area of pump design, MTH has entered into the seal-less pump market with seal-less canned versions of many of our standard products such as the SM50, SL50, ST31, ST41, ST51, SP31, and more are coming. The H Series seal-less canned centrifugal’s are a substantial line of products that encompass flows in excess of 2100 GPM, heads in excess of 410 feet, temperatures from -95°F to 662°F (350°C), and features variants to handle corrosive chemicals, slurries, refrigerants, hot oils, and any number of other fluid applications requiring heating or cooling jackets. Other custom OEM seal-less products utilize extended shaft vertical immersible or controlled leakage designs. We have also developed products for special centrifugal designs, DC applications in both seal-less and sealed versions, disk friction centrifugal’s, axial flow turbines for aerial firefighting, and submersible craft trim and drain pumps. Other engineered products and accessories include the X41 Series of seal-less canned chiller pumps, seal quench glands to extend seal life in difficult applications, special valves and suction strainers, mounting brackets, stainless steel tanks and systems, and custom piping trees and manifolds. For MTH customers, our advice is always: “if you don’t see it, please ask.”

Download our Standard Products Guide (1.26MB)

For customers whose needs fall into the lower pressure ranges, MTH is

proud to offer two lines of compact centrifugal pump products to complement

our higher pressure regenerative turbines. Towards this end, MTH has developed

the high quality, low cost 4”, 5”, and 6” C Series, semi-open

impeller, all stainless steel centrifugal pumps for the OEM market. These

units are cost competitive against stamped stainless steel centrifugal

pumps, but with a heavy duty cast impeller and casing design. Each pump

model is pre-trimmed and selected to provide the best pressure and capacity

for a given impeller and motor horsepower combination (up to 3HP and 100GPM).

Adjustment screws on the C Series casing take advantage of the semi-open

impeller design by providing the capability to occasionally renew pump

performance by tightening internal clearances and minimizing losses developed

from normal wear. These units also make use of our custom manufactured

D3 dual face motors found on our T31, E41, and E51 turbine pumps, and feature

a stainless steel shaft and a heavy duty front motor bearing. D3 Motors

also feature UL and CE approvals. The C Series standard construction is

investment cast 316 SS casings and impellers with Viton elastomers. Options

- See below.

For customers whose needs fall into the lower pressure ranges, MTH is

proud to offer two lines of compact centrifugal pump products to complement

our higher pressure regenerative turbines. Towards this end, MTH has developed

the high quality, low cost 4”, 5”, and 6” C Series, semi-open

impeller, all stainless steel centrifugal pumps for the OEM market. These

units are cost competitive against stamped stainless steel centrifugal

pumps, but with a heavy duty cast impeller and casing design. Each pump

model is pre-trimmed and selected to provide the best pressure and capacity

for a given impeller and motor horsepower combination (up to 3HP and 100GPM).

Adjustment screws on the C Series casing take advantage of the semi-open

impeller design by providing the capability to occasionally renew pump

performance by tightening internal clearances and minimizing losses developed

from normal wear. These units also make use of our custom manufactured

D3 dual face motors found on our T31, E41, and E51 turbine pumps, and feature

a stainless steel shaft and a heavy duty front motor bearing. D3 Motors

also feature UL and CE approvals. The C Series standard construction is

investment cast 316 SS casings and impellers with Viton elastomers. Options

- See below.